HIPERCAST® - The breakthrough in developing a highly durable ceramic filter for steel and heavy casting applications!

Our high performance filter!

HIPERCAST® product description

With the development of a new high performance mullite-based ceramic with the type designation HIPERCAST®, hofmann CERAMiC has created an extraordinary dry-pressed filter. HIPERCAST® allows us to achieve performance values previously considered unattainable for individual filters.

This opens up whole new possibilities in the area of foundry manufacturing technology.

- Pressed thicknesses up to 40 mm

- Thermo-mechanical qualities offer great capacity reserves with regard to fracture resistance.

- High savings potential for return materials and sand

- Casting temperatures up to 1750°C can be handled with no issues

- Flow quantities up to 15 t gray cast iron and up to 9 t spheroidal graphite iron per filter

→ actual stress limit unknown, since our tests have never been able to destroy a filter!

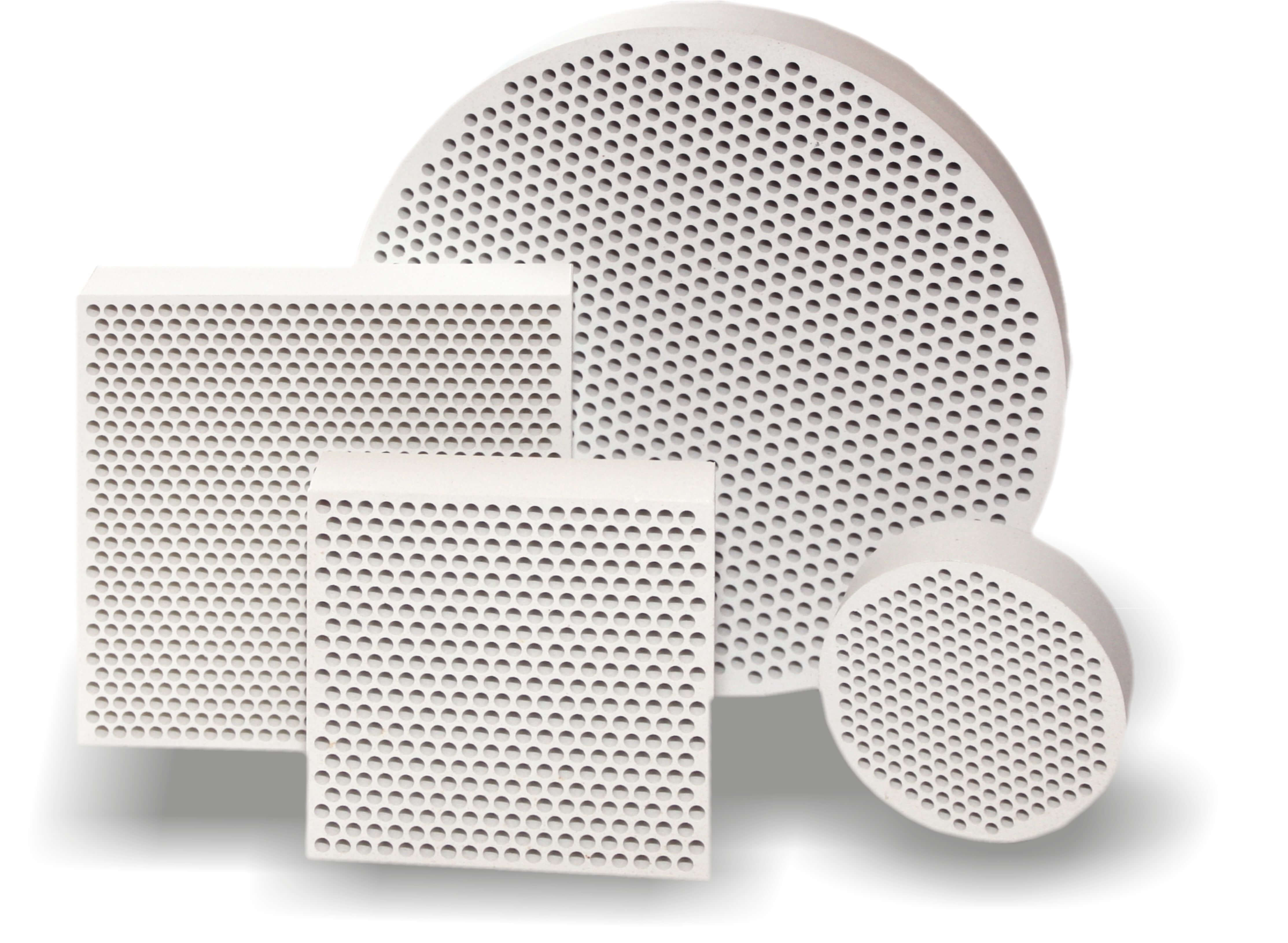

Product description round hole filters

Our pressed ceramic round hole filters are produced in our proprietary dry press process, the only one of its kind in the world, and stand out by offering the following properties:

- hydraulic properties can be calculated more precisely thanks to the exact geometry

→ reproducible mold filling with consistent cross-sections of flow

→ precise filter fit with exact installation dimensions - we can manufacture a suitable filter geometry for any application

- well-calibrated casting systems help us achieve the best possible filtration results