Services

hofmann CERAMiC offers professional support for casting technology. We support companies in calculating, designing, constructing, and simulating casting systems. Our company completes a casting technology analysis based on numbers, data, facts, drawings, and design data provided.

hofmann CERAMiC develops descriptive designs for improving economic efficiency and/or reducing errors in casting systems and corrective actions in close collaboration with the customer.

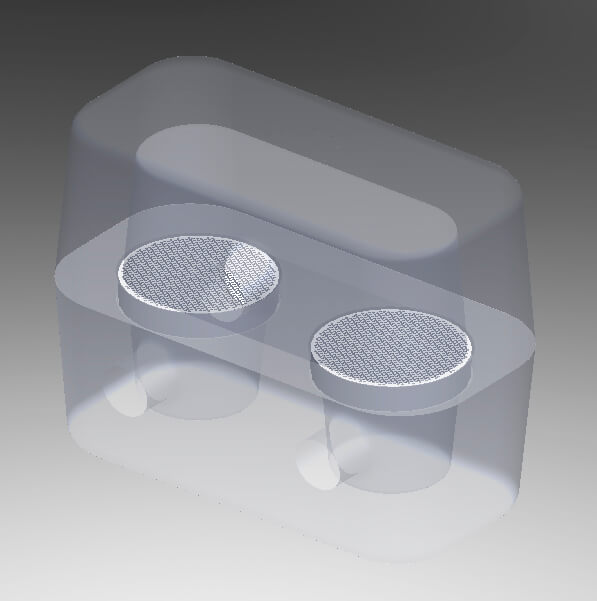

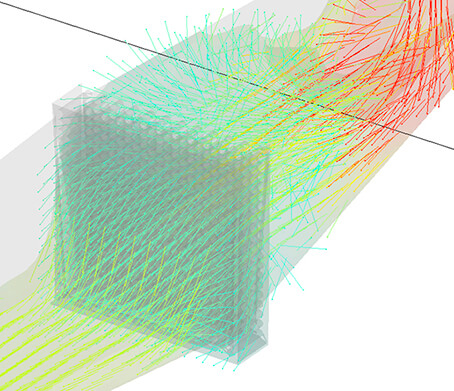

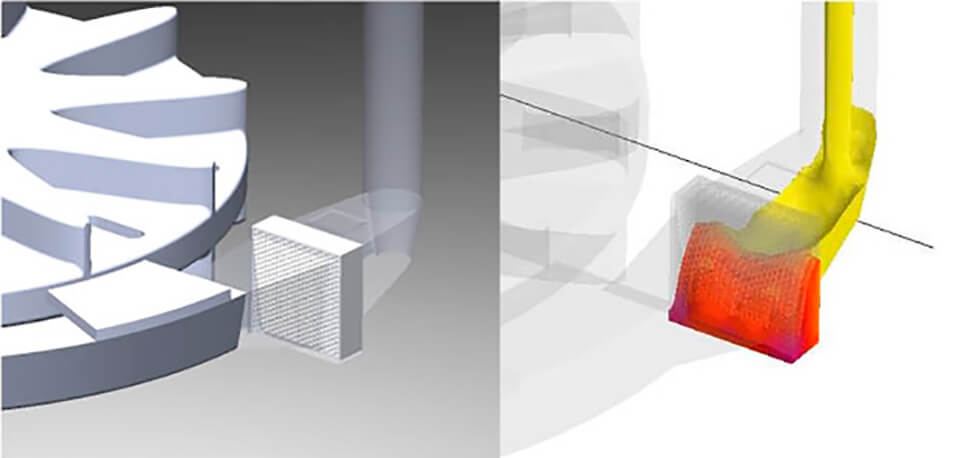

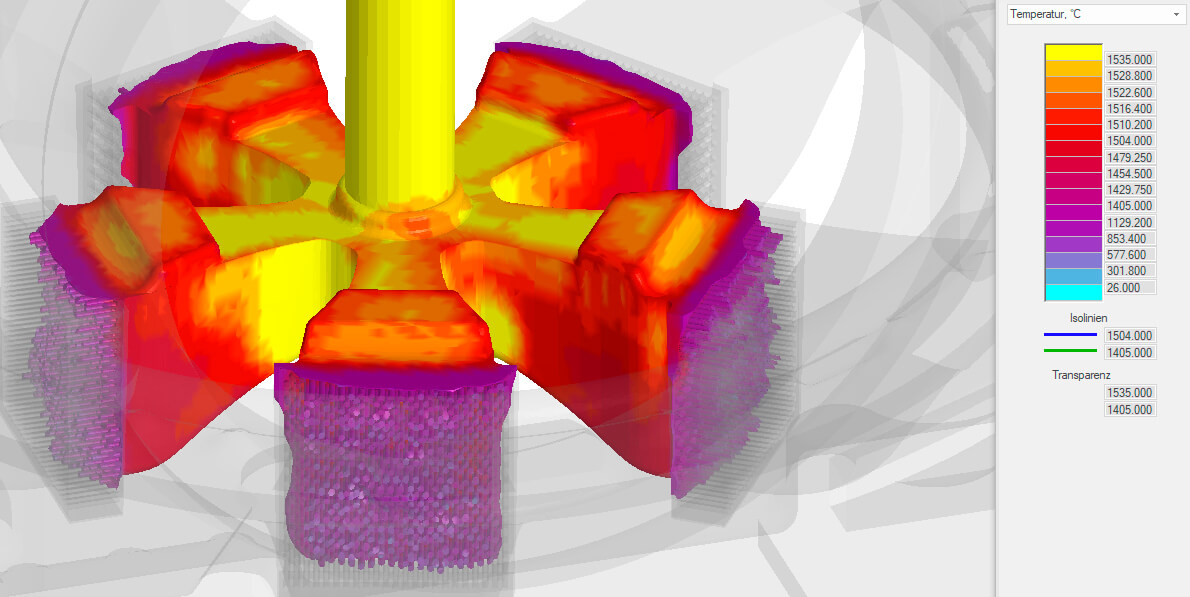

Hofmann CERAMiC uses a quick and precise simulation software to analyze casting systems, in order to discover potential areas of improvement during mold filling and solidification and optimize the casting system early on in the development phase. Reality-based 3D data sets for the casting and filter geometry are used to best simulate thermodynamics and flow characteristics between the mold form and the melt. This helps us create optimal and economical solutions early on, improving output and error costs. Almost any material can be simulated, no matter the casting process used.

The cast part production tool only goes into production if the results of the simulation analysis fulfill quality requirements so that the tool has a robust design. This lets our customers benefit from shorter development times and lower costs, as well as consistent product and process quality.

- Calculation, design, and construction of casting systems

- Form filling and solidification simulation

- Project and systematic error analysis support

- Support for product and process approvals

- Planning and completing process audits

- Technical planning for new investments and automation projects

- Project management

All services can be commissioned worldwide by agreement.

Send us a message or call us at +49 2777 / 9145-0.